Conservator Lauren Horelick, Post-Graduate Conservation Fellows Anna Weiss and Peter McElhinney, and retired treatment artisan Karl Heinzel continue to prepare the Horten jet wing to move to the Mary Baker Engen Restoration Hangar at the Steven F. Udvar-Hazy Center in Chantilly, VA. We have pushed back the Horten move to early spring in order to concentrate on finishing the Curtiss SB2C Helldiver by March 15. Conservation is studying four different aspects of the materials used to build the jet: wood, adhesives, metals, and coatings. The conservators have found three types of wood. The outer skin is made of plywood of varying shapes and thicknesses and reinforced in some areas with laminated lumber supports. These supports also serve to affix the plywood skin to the metal structural framework. Artisans during World War II used lumber in the construction of the canopy rear section, and elsewhere such as the aft end of the center section and in the air brake assembly. The small blocks of wood that serve as 'spacers' between the plywood skin and the metal airframe represent a third wood type that the conservators characterize as birch based on preliminary analysis. These blocks appear to be layers of thinner veneers stacked and glued under pressure to the required thickness. In this blog update, we will look more closely at the plywood and examine the lumber supports, spacer blocks, metals, and coatings in future updates.

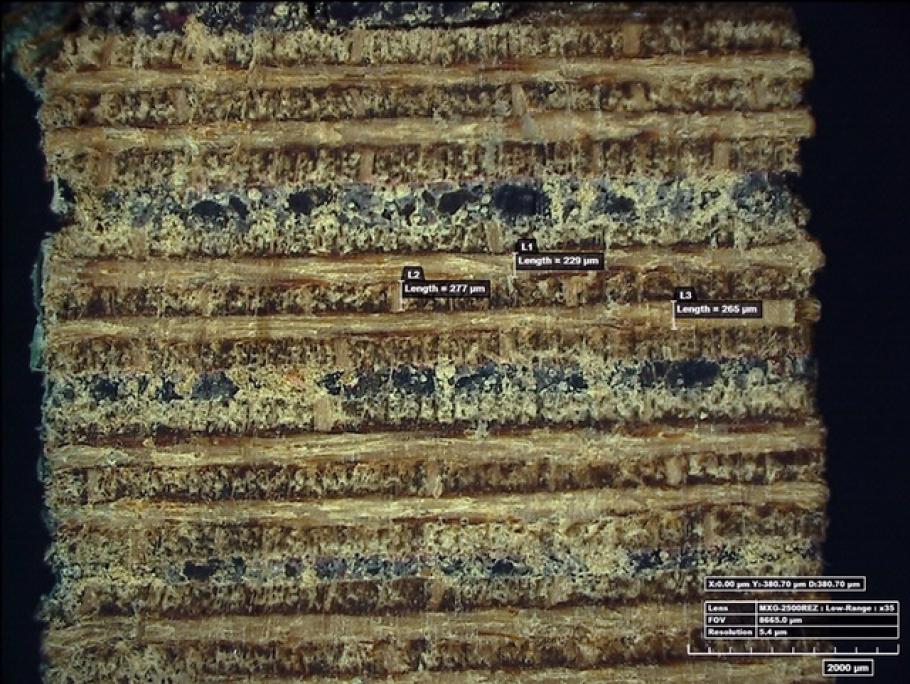

Here is a small sample cross section of plywood removed from beneath a metal engine cover near the front of the Horten. The wood is in good condition and is representative of much of the wood used throughout the plywood skin.

Here is a small sample cross section of plywood removed from beneath a metal engine cover near the front of the aircraft. The wood is in good condition and is representative of much of the wood used throughout the plywood skin. The cross section indicates the plywood in this area is made from sheets of 5-ply wood that artisans during World War II stacked and glued under pressure to create a wooden panel of the required thickness. Note the grey colored adhesive layer between each 5-ply layer. Conservators examined the sample and photographed it using a Hirox 3-D Digital Microscope. The veneer width and the number of plys used to make the individual plywood layers is consistent with the historical records, see Lacey, P.M.C., Rutherford, H.C., Pollard, G.J.T., Austin, J.B. 1945. Investigation of Targets connected with the German Plywood, Improved Wood, Shuttle Block, and Joinery Industries, British intelligence Objectives Sub-Committee Final Report No. 348. Image by Pete McElhinney. Identifying the wood species used to produce the plywood proved more complex than originally anticipated. Conservators identify wood by using the microscope to compare features visible in the three different cuts (or planes) from a sample piece of wood- the cross-sectional plane, the radial plane, and tangential plane:

The unknown sample is visually compared to known reference samples. Depending on the particular wood species, key diagnostic features, and visual patterns of diagnostic value are visible in each of the three planes described above. With thin veneers as seen above in the first photo, the exposed surface area of the cross-sectional and radial planes available for analysis is quite small. Furthermore, the penetration of glue into the wood layer, and the pressure used to make the plywood can distort some of the microscopic features useful for species identification. Identifying the plywood sample above started with the premise that the veneers most likely came from Common Birch (Betula pendula) or European Beech (Fagus sylvatica). Post-Graduate Fellow Pete McElhinney characterized the wood by processing the sample shown above to produce thin tangential sections of the individual veneers. He sliced thin sections through the 0.2 mm thin veneer ends and mounted the sections on a microscope slide. We can see one of the main differences between the two species of Birch and Beech in the tangential plane. Ray cells are involved in moving materials within the woody stem, and variations in the number of cells comprising the width of the ray can aid species diagnosis. In Common Birch, the ray structures do not exceed four cells in width whereas in European Beech, the ray structure can measure up to twenty cells wide, see Schoch,W.,Heller,I.,Schweingruber, Wood anatomy of central European Species.

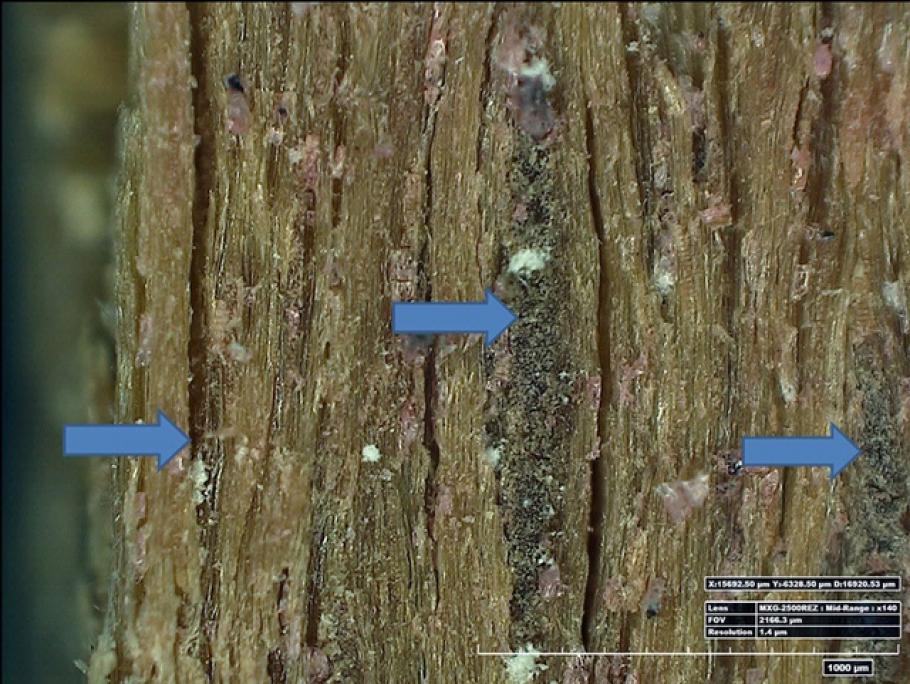

Reflected light (light source in front of the specimen) photomicrograph of plywood sample from the Horten Ho 229 V3. Arrows point to the dark areas in the sample which are made up of ray cells. Photomicrograph: Pete McElhinney, 2014

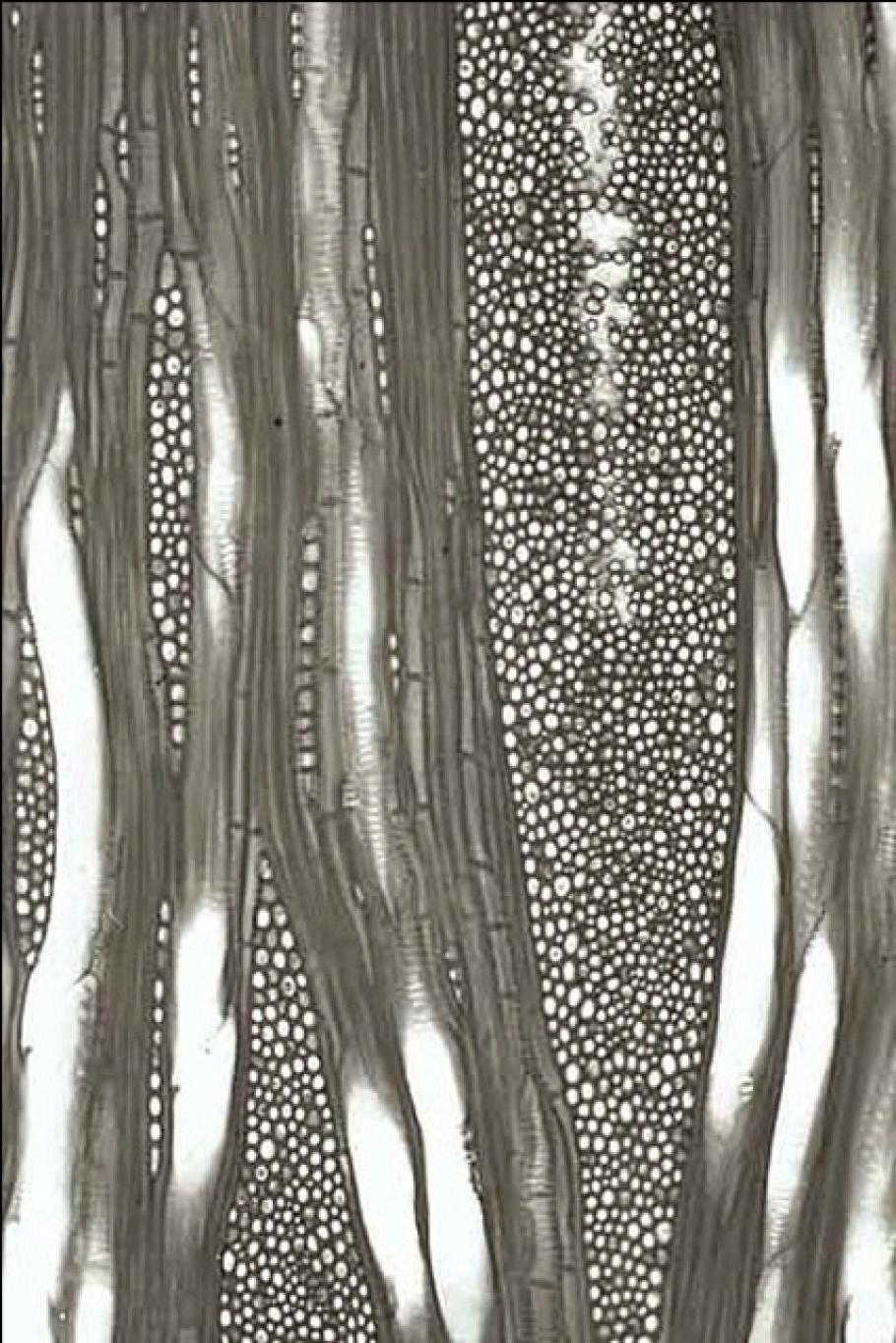

Transmitted light (light source behind the specimen) photomicrograph of plywood from the Horten Ho 229 V3. The wide ray structure, particularly clear on the left side of the image, far exceeds the four-cell width of Common Birch and is more consistent with European Beech.

European Beech, note the wide ray structure. Photo from Schoch, W., Heller, I., Schweingruber, F.H., Kienast,F., 2004: Wood anatomy of central European Species. Online version: www.woodanatomy.ch.

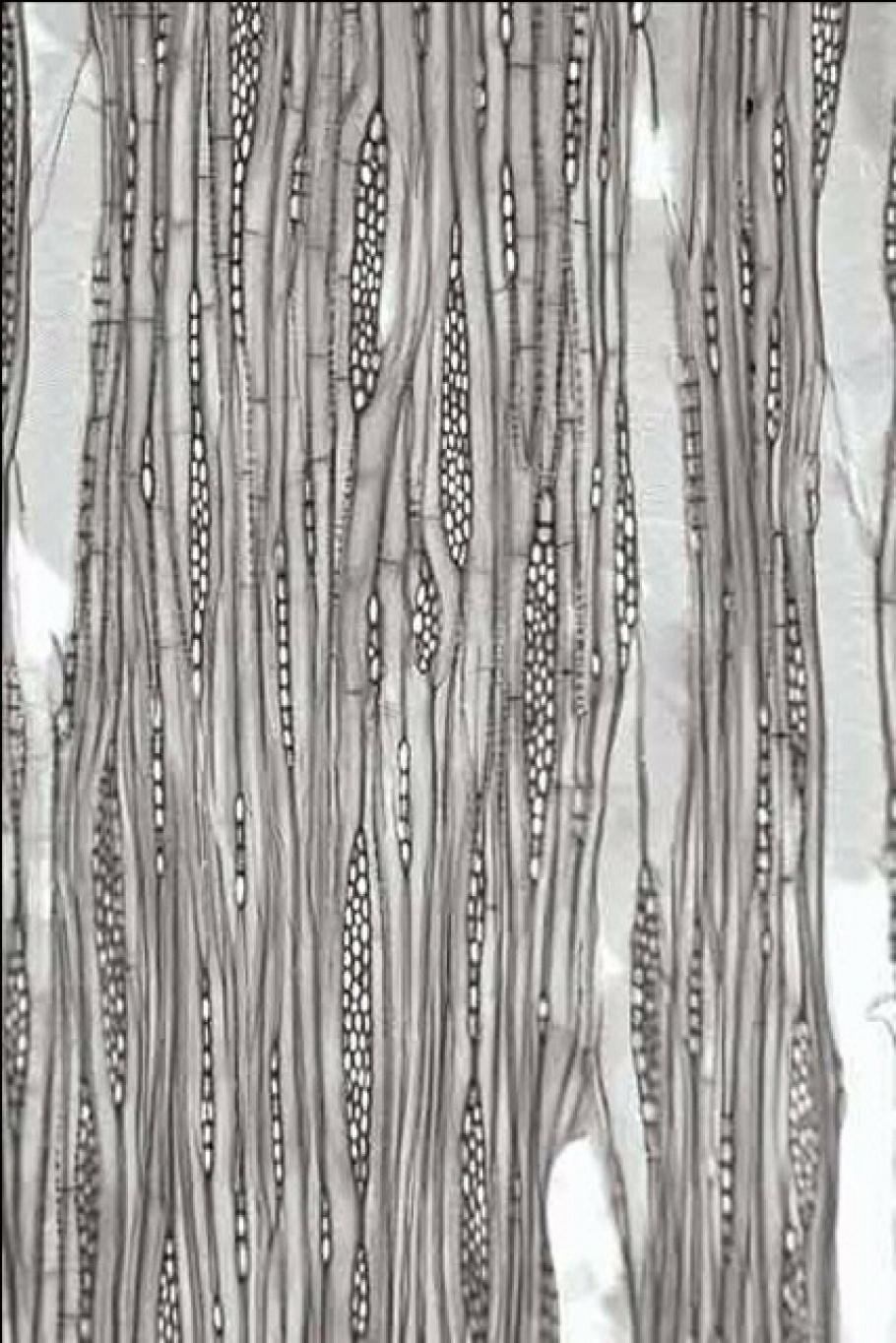

Common Birch. The rays in this tangential section are much narrower than rays in the European Beech sample. Photo from Schoch, W., Heller, I., Schweingruber, F.H., Kienast, F., 2004: Wood anatomy of central European Species. Online version: www.woodanatomy.ch.

The gallery above illustrates the different ray widths of Common Birch and European Beech that implicate Beech (in combination with historical research) as the more likely wood used to produce the Horten IX V3 plywood panels.