As previously discussed in Spiral Threads of Corrosion Overtake an Antenna Drive, a one-year conservation triage project is underway to deal with artifacts that are actively deteriorating and require stabilizing treatments prior to being permanently relocated to the new storage facility at the Steven F. Udvar-Hazy Center in Chantilly, Virginia. These artifacts include a wide range of issues to be dealt with by a team of three contract conservators, including active corrosion, mold contamination, pest management, hazardous materials, and physical insecurities.

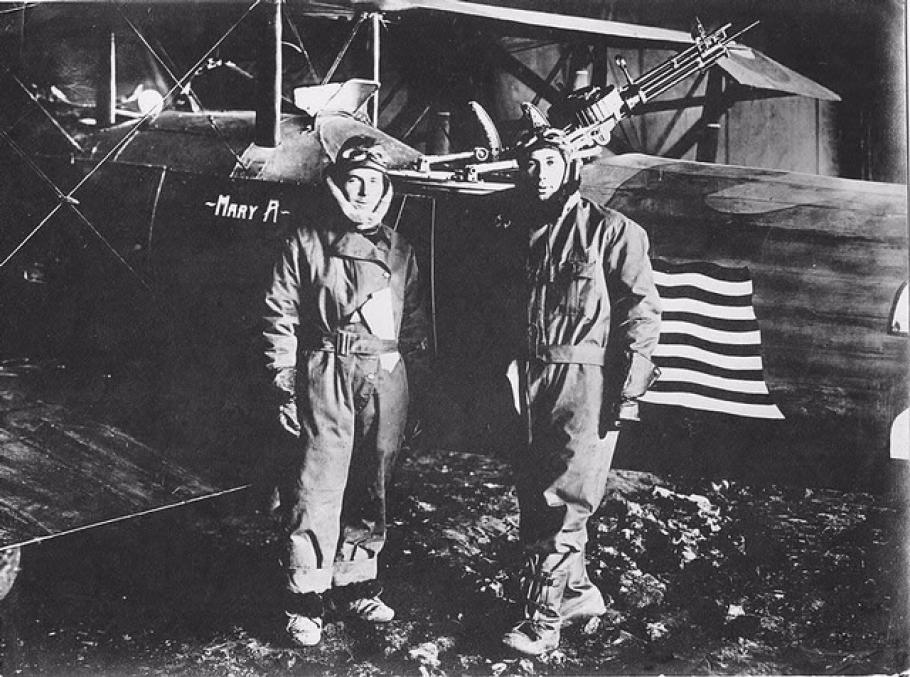

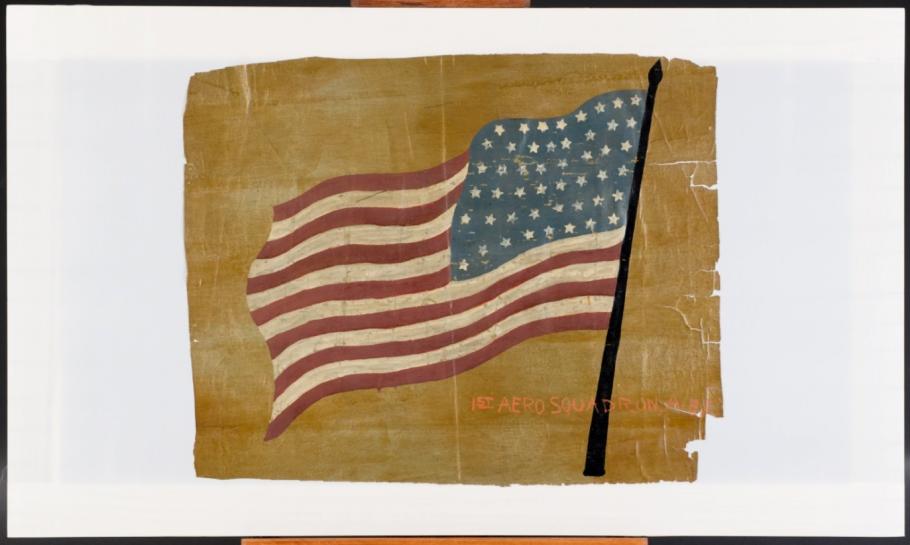

Another notable object to pass through the Emil Buehler Conservation Laboratory this summer was a portion of painted WWI fuselage fabric with squadron insignias from the 1st Aero Squadron. The fabric had been previously identified as coming from one of the first American-built Liberty DH-4 aircraft to engage in combat during WWI with a handwritten note on the rear portion of one fragment; this note indicated that the fuselage fabric was taken from the same DH-4 in which Lt. Blair Thaw (serving as the commanding officer of the U.S. 135th Aero Observation Squadron) was killed in an accident. Further analysis post-treatment has found this to be otherwise (see below).

This fuselage fabric had been identified as needing immediate conservation treatment due to a number of ongoing issues including: inaccessibility, active tearing and flaking, and surface distortions.

On arrival at the lab, it became apparent that is was impossible to fully determine the extent of damage to the fabric in its current state. A number of contributing factors had caused severe tears and fragmentation while the remaining sections were tightly rolled and folded with a memory in the material that causes it to resist uncurling. The material was gently unrolled using small weights in strategic spots to prevent tears from expanding and to allow the material to acclimate with the surrounding environment sufficiently to relax.

While we could examine and document the fuselage in this state, removal of the weights would cause the sections to immediately curl back on itself, stressing already brittle and loosely attached torn strips and fragments.

In order to return detached fragments to their original position and determine the extent of losses, we needed to find a way to relax the material.

Beyond general aging from a combination of use and physical/chemical deterioration of the cotton textile that served as the support fabric, surface distortions with shrinkage and curling were also partially related to an original surface treatment of the fabric with airplane dope. “Doping refers to the application of a tautening medium to the fabric stretched over the aircraft frame. This results in a tightly stretched surface with aerodynamic attributes” (Pierce, 2004)*. Early doping lacquers were based on cellulose nitrate, which had both benefits and detriments as a tautening agent; from a conservation standpoint, the biggest problem a nitrate-doped surface poses is continual shrinking (though at a significantly slower rate to the later butyrate-based dopes) and the stress this can place on the support fabric as well as the underlying frame.

Testing was performed with a number of different solvents and methods of application, resulting in the creation of a solvent vapor chamber. The chamber contained an atmosphere of organic solvent vapor which slowly migrated into the dope, causing it to swell and become pliable. By closely monitoring the effect, we could relax sections of the fuselage in a controlled manner; additionally, the position of weights could be adjusted during this process to further relax distortions and flatten creases. Despite the success we had with this method, we found both the cellulose nitrate coating and the cotton fabric retained some of the memory of their previous rolled and folded state. When the weights were removed and the solvent dissipated the fabric still wanted to return to its former state especially when exposed to any relative humidity fluctuations in the surrounding air.

Consultations within the conservation lab and with the curator, Alex Spencer, suggested that a larger intervention was needed. The immediate goal of this treatment was to stabilize the artifact and identify all of the separated pieces. The long-term goal was to allow the fabric to remain accessible for study and to be stored or exhibited in a safe manner. The ideal treatment solution appeared to be a lining procedure which would satisfy both long and short term objectives by providing long-term stability, reversibility and allow access for curatorial staff and researchers.

Lining, in relation to paintings conservation, is a structural treatment that introduces a new support to the back of a weakened canvas. It commonly involves the use of an adhesive in conjunction with heat, suction (negative pressure) and/or solvents. Concerns when considering a lining option “include questions of moisture content, tension and rigidity, and the difficulty of predicting the effect of providing a laminated structure to a complex layered and degraded structure as well as the ethical problem of deciding when it is appropriate to make the intervention” (Hillyer:1996)**.

For the lining adhesive, preference was given to the use of BEVA 371 (a synthetic wax and resin adhesive that remained relatively inert to moisture while also providing a non-impregnating, strong surface bond) as a lining adhesive that could be applied either in a gel form or as a pre-cast film to the rear face of the fabric. Since the adhesive is thermoplastic, an iron could be used to heat-set the bond between the fabric and the lining. Once the large sections of intact fabric were attached to the lining fabric, the smaller separated pieces could be positioned in their original locations.

As a lining material, an airplane fabric called Ceconite (a, woven Dacron polyester) was chosen because of its strength, long-term chemical stability and its ability to be “heat shrunk” over a support structure at a specific temperature. Unlike cotton or linen, it does not stretch and does not react to changes in humidity. The Ceconite liner was pulled and tacked onto a custom-built strainer prior to the heat activation of the adhesive. Final tautening was only performed on open areas where the fuselage fabric was not attached and then as a final step to tauten up and remove wrinkles from the surface.

An immediate result of the conservation treatment was that it made available updated and higher quality images of the fabric that spurred additional analysis by the collections department. Inconsistencies in terms of written language phrases, camouflage design, wear patterns, insignia design, and squadron information all indicated that the fabric had not come from an American-built DH-4 but from a Salmson 2.A.2 in which Lt. Thaw had a forced landing during his time with the 1st Aero Squadron, (probably on July 7, 1918). Likely confusion from a number of possible sources led to the misidentification in the note.

This project is Phase I of a multi-phase plan and is supported by the Smithsonian Collections Care and Preservation Fund, administered by the National Collections Program and the Smithsonian Collections Advisory Committee. Special thanks to Malcolm Collum for his assistance in the development and implementation of this treatment project.

* Pierce: 2004, Pierce, Andrew. Avoiding that shrinking feeling: adopting a chemically unstable material for conservation; published in BigStuff: Care of Large Technology Objects, Editor: Alison Wain, Venue: Australian War Memorial, Canberra, Australia, Date: 29.09.2004 – 01.11.2004, ISBN: 09751904 3 1;

** Hillyer: 1996, [paraphrasing of Jonathan Ashley-Smith lecture in Review: Lining and Backing - The Support of Paintings, Paper and Textiles, UKIC Conference, London, 1995];